Rotary positioner tables are an often-overlooked necessity in many workshops. They can prove to be invaluable to welders, manufacturers, crafters, and more, since the rotary motion technology behind them has many uses and applications across various industries.

As the leading manufacturer of standard and custom rotary systems with varying purposes, IntelLiDrives delivers components of the highest quality, and our rotary positioner tables are unmatched in the industry.

Let’s take a closer look at the basics of rotary positioner tables, their uses, specifications, and applications in different industries.

Uses of Rotary Motion Technology

Rotary motion technology is essential in automation equipment, machine tools, medical devices, robotics, automotive and aerospace industries, as well as many others.

The most essential rotary motion technologies include:

- belt drives

- direct drives

- cam indexers

- planetary gearheads

Rotary positioner tables using belt drives are often a more affordable option that offers high speeds, capable of easily reaching the speed of 1000 rpm. The high quality of materials guarantees their durability, and the teeth of the belt drives ensure efficient transfer of torque without slipping.

Rotary positioner tables with direct drives come with their own servo motor. They’re easier to maintain since they use fewer components, and are therefore easier to repair as well. They do come at a higher price point and have limited load capacity. Direct drives are ideal for medical equipment or factory automation industries, for example.

Cam indexers are ideal for high precision applications like dial machines, conveyors, and the like. A fixed index can indexer is great for accurate positioning, while a fully programmable can indexer is suitable for flexible motion patterns.

Planetary gearheads are essential for any motion control application, as they offer a high level of torque and volume. They’re easy to control and are very precise. However, they’re often very expensive.

The Basics of a Rotary Positioner Table

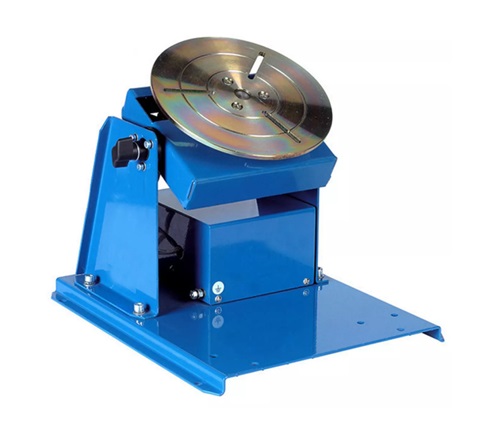

Rotary positioner tables, or welding positioners as they’re often known, are usually designed to allow simultaneous work on 2 different surfaces. The front and back sides of the table are often of different sizes, with the front being larger and ideal for placing bigger parts, and the back side being smaller and great for smaller objects.

Controlling the movement of a rotary positioner table is simple since it has two steppers. One is used for moving the table to the left, and the other to the right.

Rotary positioner tables come with an emergency button that deactivates the machine immediately if needed. They also allow for easy regulation of the rotary speed to suit specific needs.

The tables are easily adjustable, and various parts of the machine can be changed according to the user’s needs. This allows for easier maintenance, and different parts can be repaired if needed.

Rotary Positioner Table Operation and Specifications

Primarily, rotary position tables can usually move between 0 and 150 degrees. Depending on the type chosen, some can have a more limited movement range and go up to 100 degrees only. The circular movement allows for easier cutting, and the user can add or move the pieces they’re working on very quickly thanks to the tilt of the table.

The added bonus of rotary positioner tables is that they come with their own engine. You can commonly find versions with either DC or AC engines, and the choice depends on your needs and preferences. Smaller rotary positioner tables, of course, come with less powerful engines, whereas the bigger ones can reach the speeds of 15 rpm.

Rotary positioner tables are designed to operate at slower speeds so that the welder, or another user, can remain in one position and work continuously, ensuring consistent quality of work and great accuracy.

Most rotary positioner tables today, however, are extremely adjustable and powerful, meaning that the speed can be manually set. This allows for easier uses across varying industries.

What Are Rotary Positioner Tables Used For?

Their small size and powerful engine make rotary tables useful in many workshops. They’re a great option for those who work in smaller shops and need to optimize their space, as they can be used as stationary tables, or of course, provide rotary motion when needed.

Since they’re often called welding positioners, their primary use is quite obvious. They can prove to be greatly beneficial to welders, but that’s not their limit.

Rotary positioner tables are highly versatile and can prove to be useful in manufacturing, crafting, metal industry, etc. There are many larger variations available that don’t require manual operation and that can be exceptionally useful in factories.

Rotary positioner tables have varying specifications and features, and depending on your industry and type of work, they can offer many benefits and make your workload easier to handle.

Comments